JEC Show in Paris

Meet us at the JEC Show in Paris (March 6th to 8th 2018)! We will be happy to present you…

MaruHachi Group with its headquarters in Fukui, Japan, founded in 1936, is a family-owned developer and manufacturer of composite materials with approximately 80 employees, who was traditionally active in textiles. Some 10 years ago, MaruHachi decided to diversify into the fascinating sector of advanced materials, namely into the thermoplastic composites sector, in form of tapes, sheets and near-net shaped preforms.

This business is being expanded into the European market since most of the innovations are coming from that region. The offering includes products based on unidirectional reinforcement glass, carbon and aramid fibers with matrices ranging from PE, PP, TPU, PA6, PA/L, PPS, PEI, PES, LCP to PEEK. In 2014, MaruHachi has won the JEC Innovation Awards for their high-pressure vessels Type IV.

In Europe, MaruHachi is member of the AVK. As a business partner of the AZL, MaruHachi actively participates in the business platforms „Composite pipes and vessels“ and „Thermoplastic composites“ where some 20 partner companies along the entire value chain establish together with relevant research institutes common research and development projects, technology comparisons as well as market overviews and their development.

In Japan, MaruHachi is networking with these universities and institutes: Kyoto Institute of Technology, Tokyo University, Nihon University, Osaka University, Doshisha University, Fukui University, Innovative Composites Center.

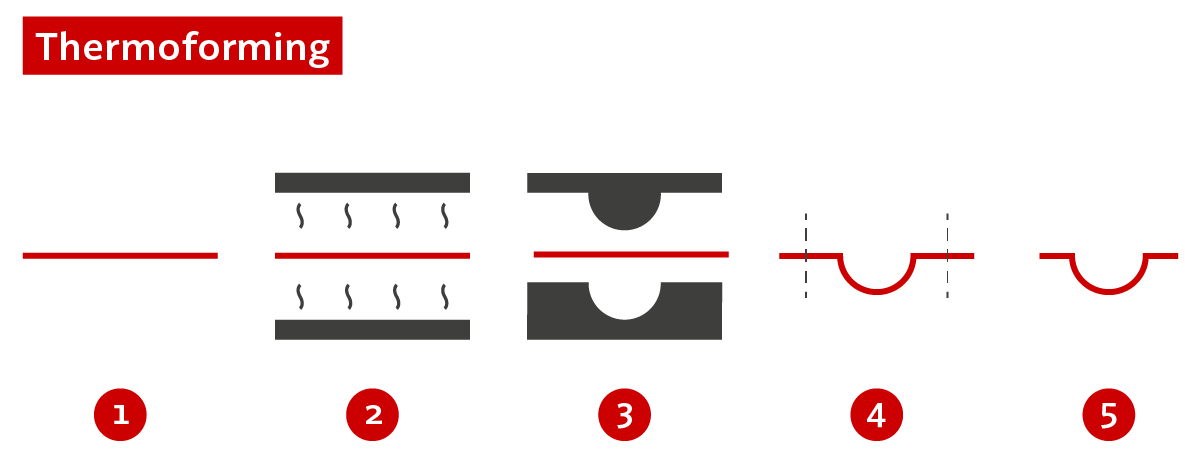

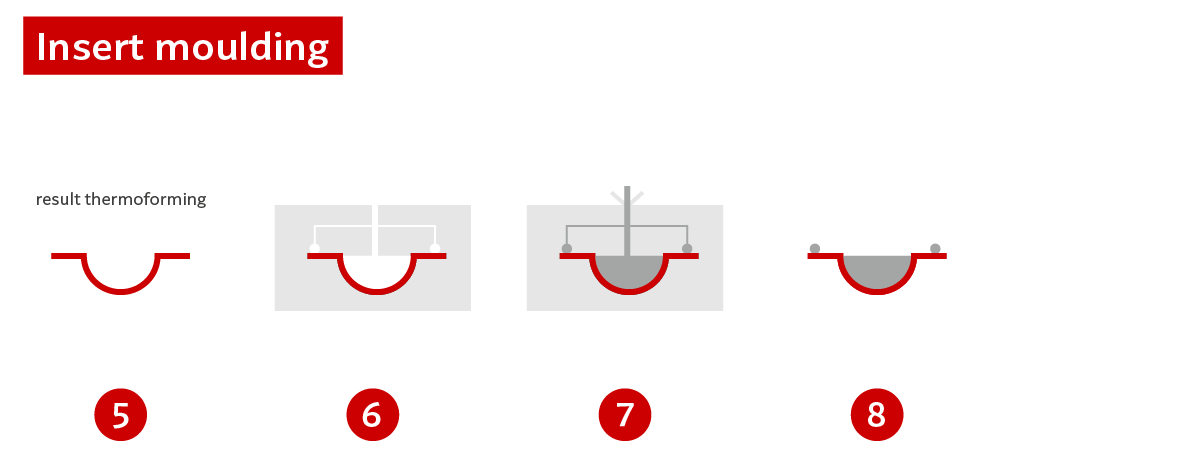

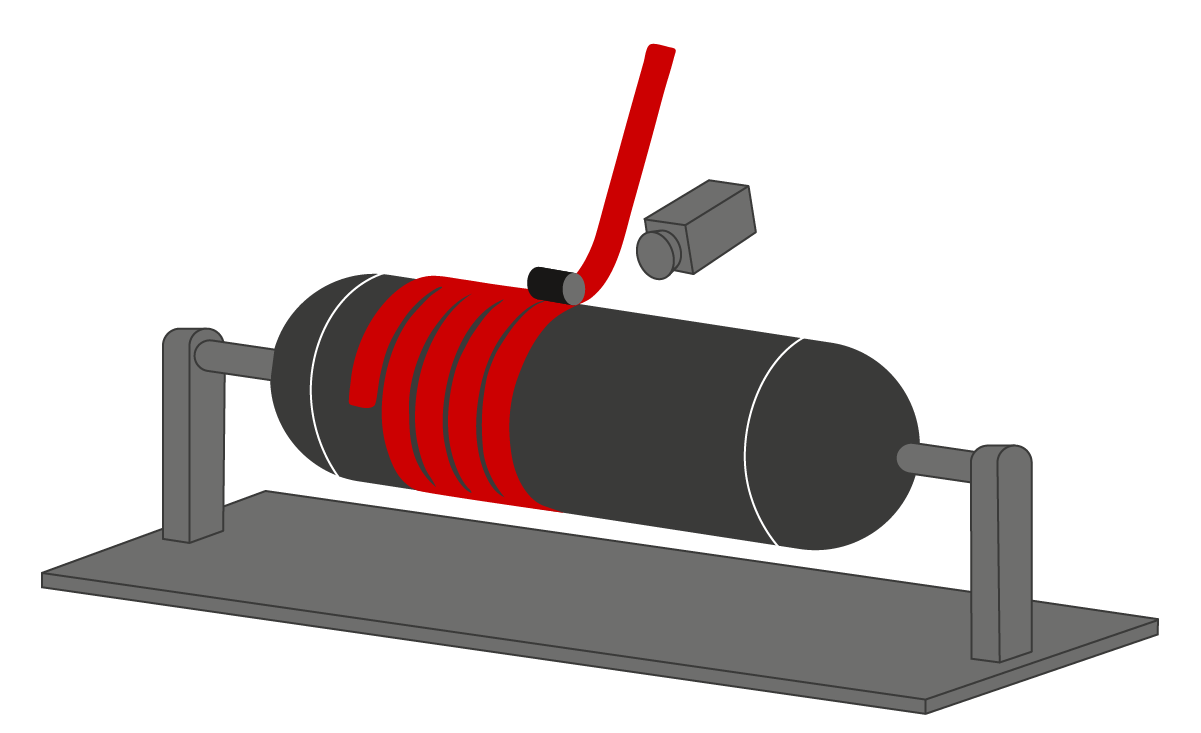

For high-volume production series with more than 100,000 units p.a., tailored material functions and a constant product quality, MaruHachi uses three different technologies: thermoforming, insert moulding (hybrid moulding) and tape winding (tape lay-up). These technologies allow to produce large complex lightweight volumes in short cycle times, while being cost efficient and environmentally friendly.

With this technology, composite parts and composite inserts are produced. MaruHachi can supply parts from 1 cm2 up to 1 m2 in size with a tolerance of ± 0.05 mm. Component thicknesses may vary from 50 µm to 1 cm.

Complex high performance parts are manufactured with this technology, where CFRTP is combined in an injection moulding process with engineered thermoplastic resins.

MaruHachi tapes can be used for laser-based filament winding of pipes and vessels or in a laser-based tape placement process for the manufacture of 2 D and 3 D preforms, laminates and parts.

Meet us at the JEC Show in Paris (March 6th to 8th 2018)! We will be happy to present you…

AMAC: Strategic Partnership with Japanese thermoplastic composites material manufacturer MaruHachi for new business developments in Europe As of July 1st,…

CEO MaruHachi Group

Mobile +81 90 8969 2401

toshi@maruhati.co.jp

Manager European Market

AMAC GmbH

Phone + 49 241 912 9022

amac@effing-aachen.de

www.amac-international.com